The following information was created in partnership between Fike and Kardex Remstar, manufacturer of automated storage and retrieval systems.

The modern warehouse looks and operates a lot differently than it did even just a decade ago, and with that progress comes a new kind of challenge: fire protection.

Traditional warehouse fire suppression methods were designed for open spaces filled with static shelving and clear airflow.

However, today’s automated storage systems are enclosed, high-density and packed with electrical and mechanical components. These compact structures make operations faster and more efficient for warehouses. But they introduce unique fire suppression challenges that standard sprinklers and detectors simply weren’t built to handle.

That’s why manufacturers, integrators and safety professionals are rethinking what fire protection should look like in the age of automation.

The Unique Risk of an Enclosed Storage System

Automated storage systems like the Kardex Shuttle Vertical Lift Module (VLM) are engineered for precision and efficiency. They make the most of vertical space, sometimes stretching 30 feet or more, and bring stored items directly to the operator through a secure, enclosed structure.

“The same qualities that make a Vertical Lift Module so efficient - dense storage, enclosed design and high-speed automation, are also what make fire suppression more complex,” says Calvin Bowers, Senior Director of New Business at Kardex. “That’s why it’s critical to design protection systems that understand how these machines actually operate.”

In a VLM, your fire suppression system needs to solve for:

- Limited airflow: The enclosed design can restrict ventilation. This is a huge benefit for storing sensitive or high-value goods, as they are protected from dust and debris from the warehouse floor. But this design can also allow heat and smoke to accumulate quickly and invisibly.

- Dense storage: Tightly packed materials mean that warehouses can store much more in a smaller footprint. But the high-density storage can feed a fire while making it harder for water or suppressant to reach the ignition source.

- Sensitive equipment: Electrical components, motors and sensors are perfect for storing in a VLM. But these items can act as potential ignition points and can be easily damaged by water or chemical residue.

- Detection delays: Standard smoke detectors located in open ceilings may not detect a fire inside a closed unit until it’s too late.

Recognizing these challenges, Fike and Kardex collaborated to rethink the entire approach to warehouse fire protection, developing a specialized system that integrates seamlessly with VLMs to deliver rapid, residue-free suppression precisely where it’s needed.

VLM Fire Suppression Systems

Fike Solutions Group (FSG) worked closely with Kardex to better understand the ASRS, determine the possible fire risk and analyze the unique challenges that may be posed to the fire protection system. FSG then designed and tested a comprehensive solution that pairs Fike’s advanced detection and clean agent technology with Kardex’s automated storage architecture, creating a complete safety system that is fast, precise and green.

The configuration combines several key components, each engineered to perform a specific role within the VLM environment:

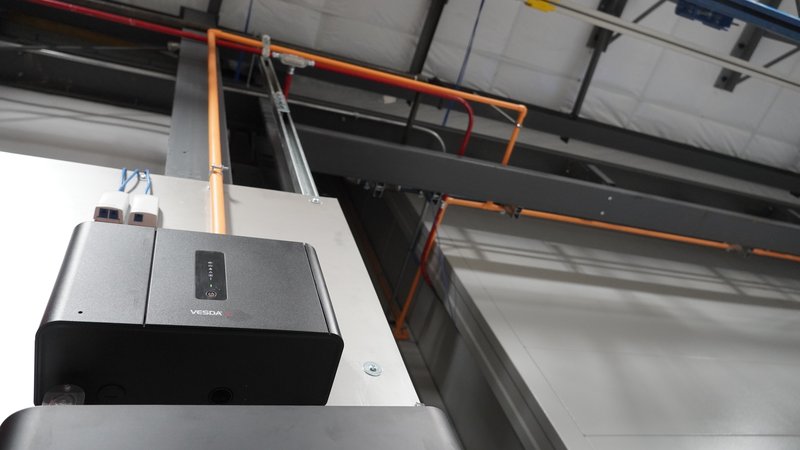

- Xtralis VESDA Air-Sampling Smoke Detection: Continuously samples air inside the VLM for microscopic combustion particles, identifying potential ignition long before visible smoke appears.

- Fike Cheetah Xi™ Control Panel: The intelligent core that coordinates detection, alarm and suppression for rapid and accurate response, minimizing false activations.

- Fike Inert Gas Suppression (IG-100 – Nitrogen): Deploys a 100 percent nitrogen clean agent that extinguishes fire by reducing oxygen concentration, leaving no residue and causing no harm to electronics or sensitive materials.

- Fike Horizon™ ASRS Nozzles: Precision-engineered nozzles designed specifically for Kardex systems, ensuring uniform agent distribution within the VLM’s interior without interfering with tray movement or automation mechanics.

These elements were validated through extensive testing and refinement, simulating real-world fire conditions to verify system performance and coverage. The result is a specialized fire protection solution that meets both Kardex’s operational standards and Fike’s rigorous safety benchmarks.

“Protecting automation isn’t just about reacting faster. It’s about designing smarter,” says Bowers. “Fike’s team understood how critical uptime and cleanliness are to our customers. They want to protect their inventory from fire damage, of course. But they also want to protect their inventory and machine from water damage. Fike built a system that safeguards both.”

Fire Protection for New and Retrofitted VLMs

For new Kardex Shuttle Vertical Lift Module (VLM) installations, the Fike suppression system can be built directly into the machine’s architecture. This integrated approach allows for:

- Optimized nozzle placement, ensuring uniform clean-agent coverage without interfering with internal movement or sensors.

- Tighter coordination between the VLM’s control software and Fike’s detection system for faster, more precise response.

- Streamlined compliance, as both systems are validated together under Kardex’s design and performance standards.

This design-stage integration represents the future of safety in automation, one where fire protection is not an accessory, but a built-in element of machine performance.

Also, while integration is ideal for new systems, the majority of facilities running automated storage today are doing so with existing VLMs already in service. That’s why Kardex and Fike made retrofit capability a central part of the solution.

Retrofitting allows operators to upgrade safety without majorly disrupting their daily operations. This allows warehouse managers to focus on protecting their teams, inventory and compliance without sacrificing performance.

Fike offers the ability for existing Kardex customers to gain access to the same high-performance protection as new installations, without needing to replace or completely redesign their equipment.

“The partnership with Fike gives our customers options,” explains Bowers. “Whether they’re installing a new system or upgrading an existing one, they can choose the protection level that fits their operation, knowing it’s been engineered, tested, and approved by both Kardex and Fike.”

Protect Your VLM From Fire Today

Automation may be redefining how warehouses move, store and deliver materials. But it’s also redefining how we must protect them. Vertical Lift Modules (VLMs) bring speed, density and control to modern storage, yet their enclosed design demands equally advanced fire protection.

That’s where Fike’s engineered suppression systems stand out. Purpose-built for automated environments, our solutions combine early smoke detection, intelligent control and clean-agent suppression to safeguard both your equipment and your inventory without disrupting operations.

As automation continues to rise, so will the need for protection that’s fast, clean, and precise. With proven technology and decades of expertise, Fike is helping facilities protect the next generation of storage systems - one Vertical Lift Module at a time.