Power Generation

Generating power requires complex systems of various equipment that each possess their own unique fire hazards. To protect these potentially dangerous environments, Fike recommends the following detection and suppression solutions.

Wind Turbines

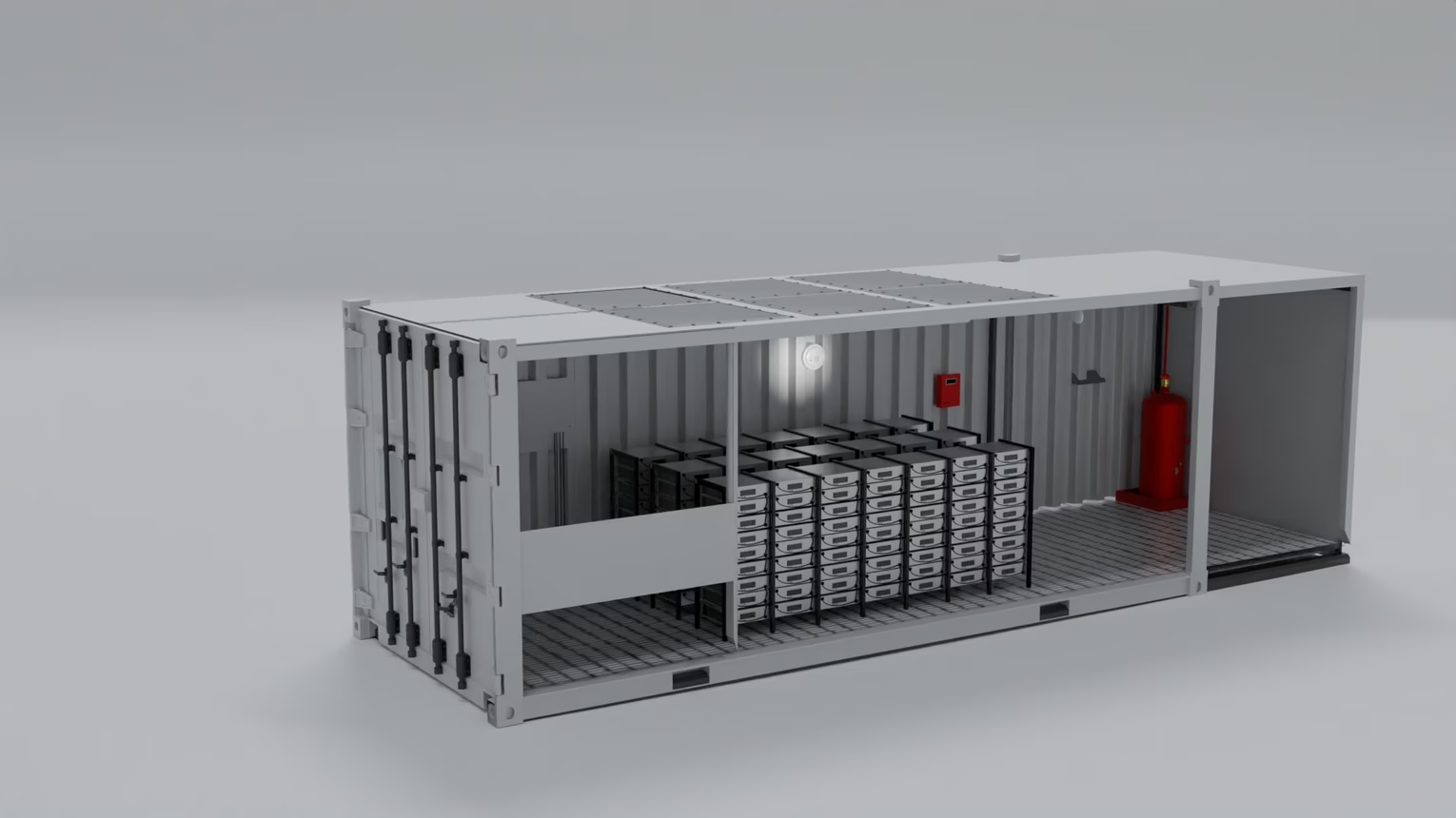

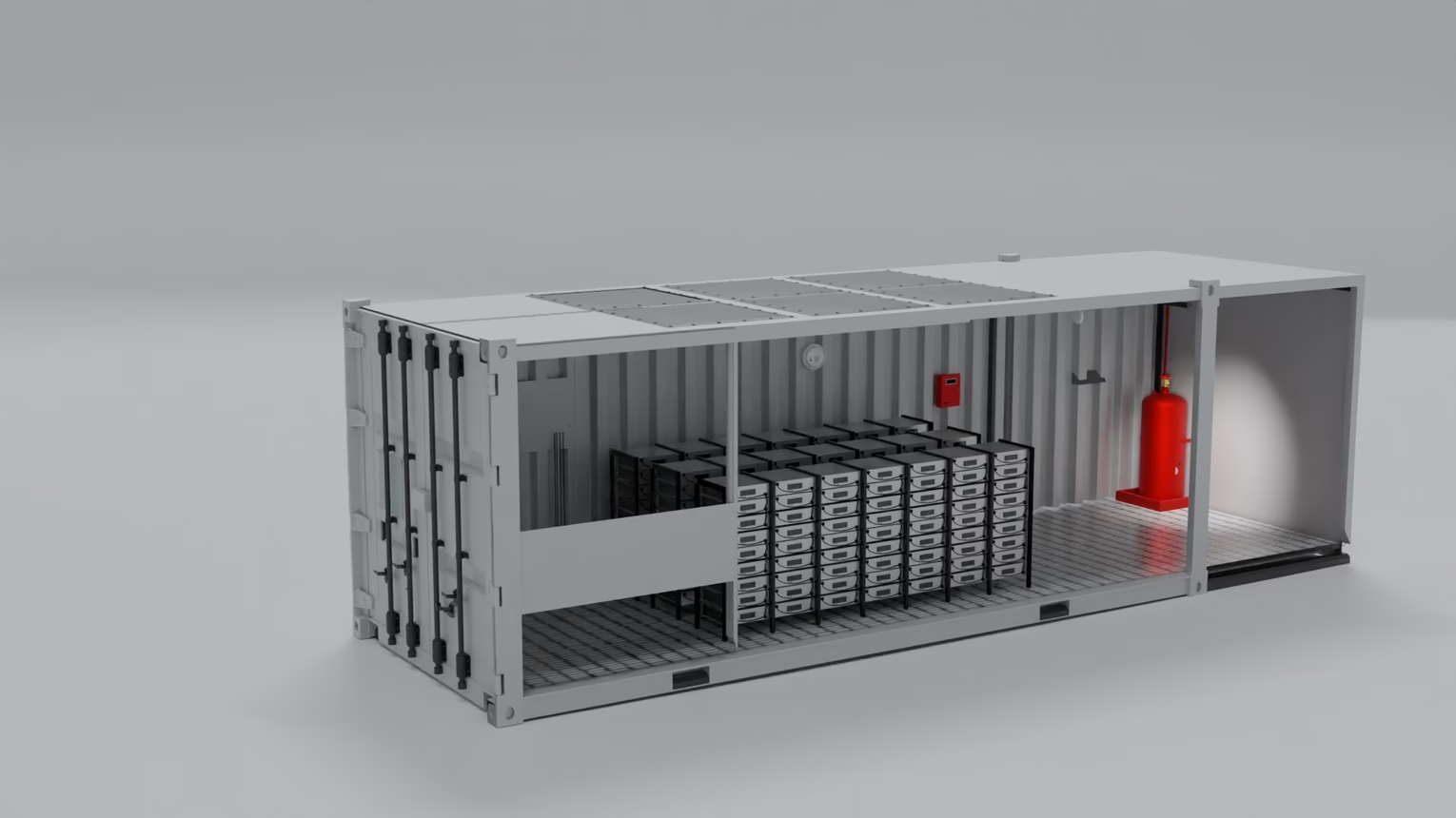

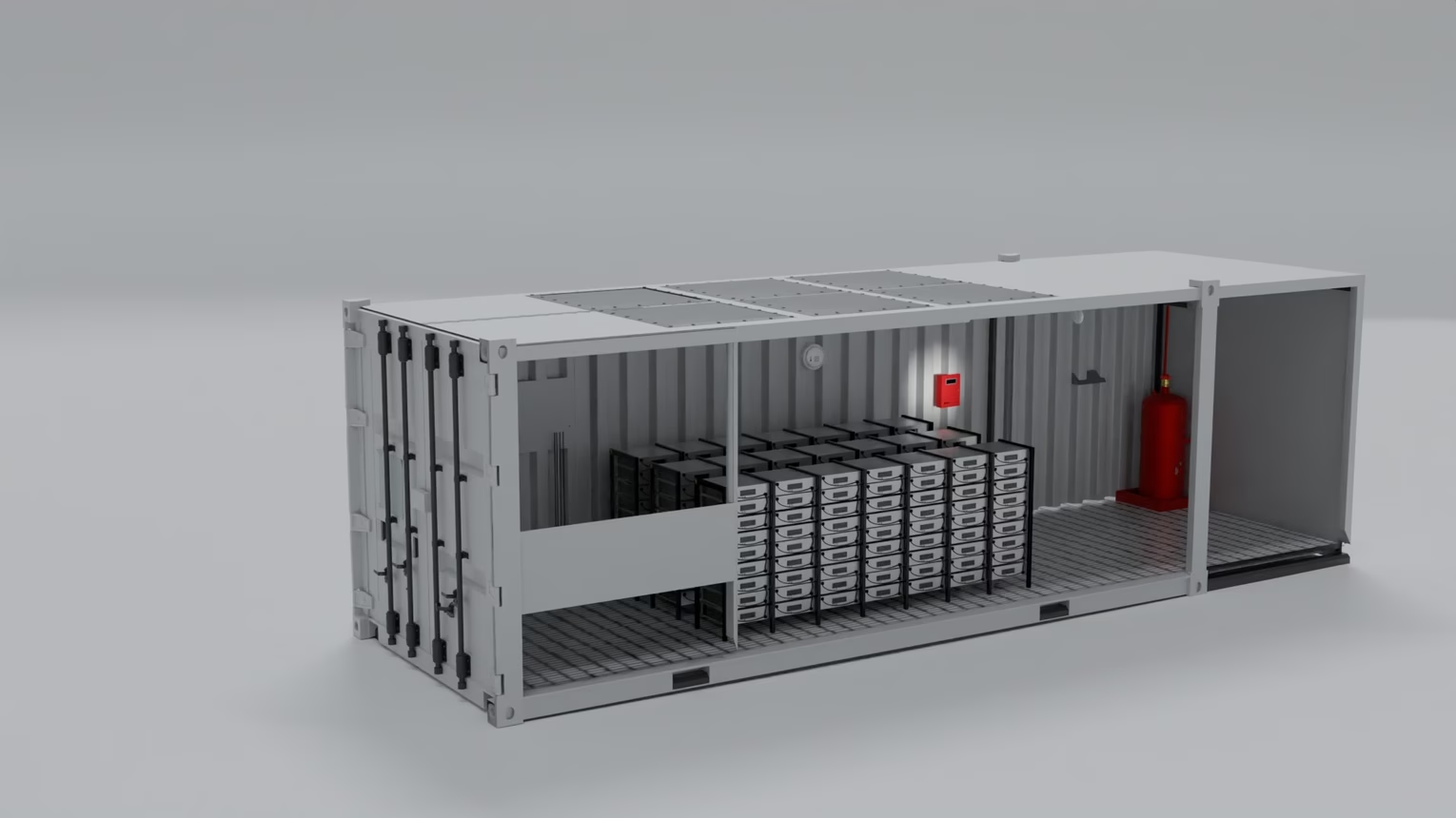

Wind Turbine Energy Storage

Power Plants

Coal, Nuclear Fision, Natural Gas

With their various equipment, fuels and methods of conveyance, power plants are among the most complex industries for fire protection.

- Storage

-

Fuel such as coal or biomass is stored in bulk where deep-seeded, obscured fires may occur. Thermal imaging cameras can identify hotspots within these storage bins, notify personnel and shutdown power before the smoldering product is conveyed further downstream into more combustible atmospheres. Furthermore, if a coal mill is used to crush the fuel, an explosive combustible dust hazard may also be created which would likely require an explosion suppression and isolation system.

- Transportation

-

Conveyors transport fuel such as coal into the boiler. Misaligned bearings on the conveyor may create sparks or overheated surfaces, which could cause the fuel to burn prematurely. Thermal imaging cameras can be applied to monitor surface temperatures or malfunctioning equipment, or linear heat cables can be run along the conveyor to detect abnormal heat. Upon detection, a fire control panel can shut down power to the conveyor or activate suppression systems.

- Hazard

-

A steam turbine’s lubrication oil system is the most likely fire hazard, as various malfunctions can result in smoldering fires or even spray fires. Similar fires may occur from the lube oil skids themselves. Fike flame detectors are ideal for these applications because of their ability to detect fires from up to 230 ft away in mere seconds. Once detected, a Fike Micromist system may discharge to suppress the fire and provide a prolonged cooling effect to ensure the fire doesn’t reignite.

- Identification Of Elevated Temperatures

-

The bearings on a generator may become misaligned and cause friction, creating sparks or hot surfaces. Thermal imaging cameras may be used to proactively identify elevated temperatures, which may indicate the need for maintenance. In an emergency situation, thermal imaging cameras may alert personnel, discharge sprinkler or suppression systems, and shutdown power to the generator.

- Detection Of Fire

-

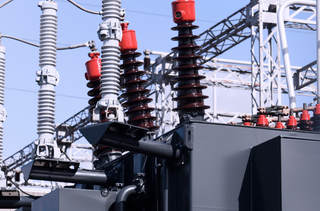

High-voltage transformers are at risk of experiencing devastating fires, so quick detection is required in these environments. Linear heat cables may be fastened throughout the space to detect abnormal temperatures. When a fire is detected, power will be shut down to the transformers and safety personnel will be notified.

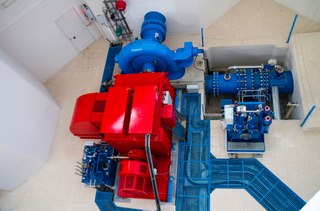

Hydroelectric Power Plants

Coal, Nuclear Fision, Natural Gas

Much of a hydroelectric power plant’s equipment and components are located underground, making the detection and suppression of these obscured fires particularly important. For example, in 2012 at the 84-MW Ronald B. Robie (Thermalito) Pumping-Generating Plant in Oroville, CA, a fire occurred which burned for 48 hours. The cause: a cable tray which went undetected for long enough to result in hundreds of millions of dollars in damages.

- Generators & Oil Rooms

-

Generators and Oil Rooms - The bearings on a generator may become misaligned and cause friction, creating sparks or hot surfaces coated with flammable oil. Flame detectors are ideal for quickly identifying fires, or thermal imaging cameras may be used to proactively identify elevated temperatures or misaligned parts. Once detected, a Fike DuraQuench system may discharge to suppress the fire and provide a prolonged cooling effect to ensure the fire doesn’t reignite.

- Control Room

-

Control rooms are often protected with inert gas because of its ability to quickly suppress fires which may be found in these environments and in a way that is safe for people. Depending on the size of the control room, VESDA air sampling or basic spot detection may be used. Finally, to protect any electrical cabinets in the control room or throughout the facility, Fike Small Space Suppression may be used. Any fire that occurs inside the cabinet will melt a hole in the system’s heat-reactive tubing, which will then release chemical agent directly onto the fire.

- Cable Trays

-

Cable trays are particularly concerning because they are often obscured from view and may result in a fire for several minutes or even hours before being detected. Linear heat cables may be run alongside cable trays to quickly identify the location of an electrical fire, which may then alert personnel and activate any number of appropriate suppression systems.

- Tunnels & Subfloors

-

Some underground environments have ceilings intended to shed water and are therefore unable to be penetrated by spot detectors or air sampling pipes. In these situations, flame detector cameras equipped with Fike Video Analytics may be installed on the walls to provide early warning detection of smoke or flames.