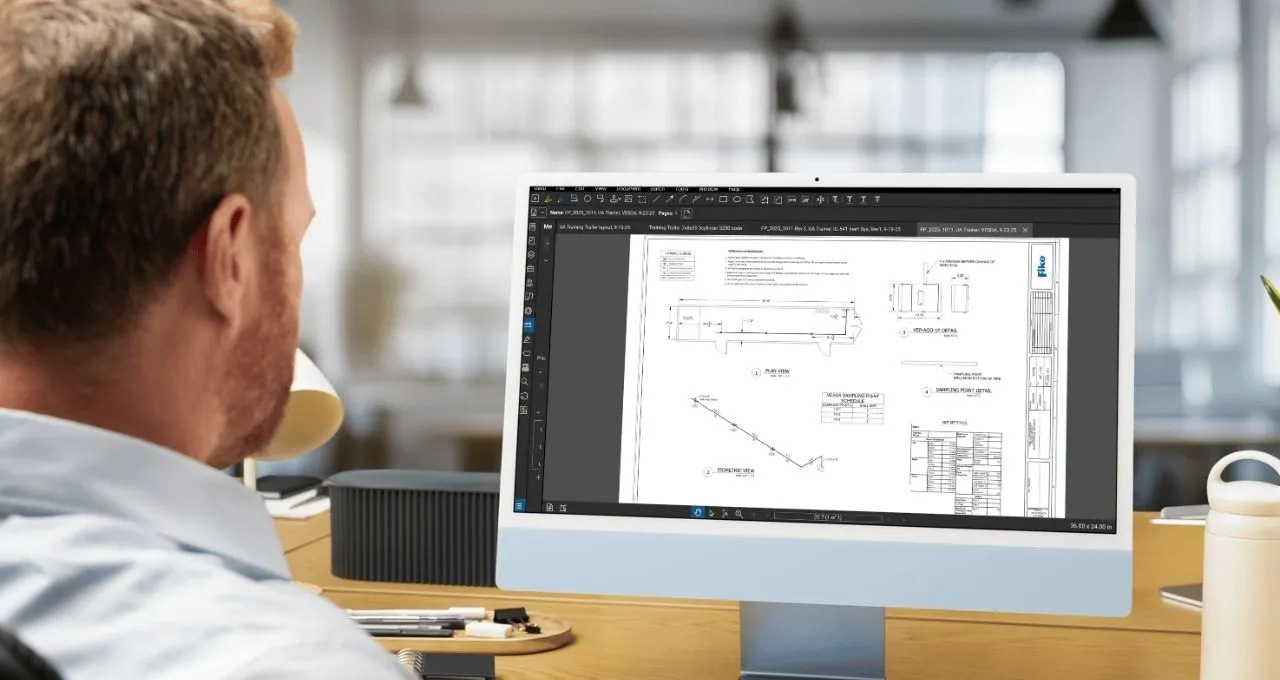

Special Hazard Consultancy & System Support

Do you have a challenging industrial process or high-value asset that requires a professional mitigation strategy?

Fike Solutions Group (FSG) is your trusted global risk-management partner for industry-leading research, engineering, design support and tailored solutions to eliminate catastrophic loss of life and damage to mission-critical assets.

Fike Solutions Group Offerings

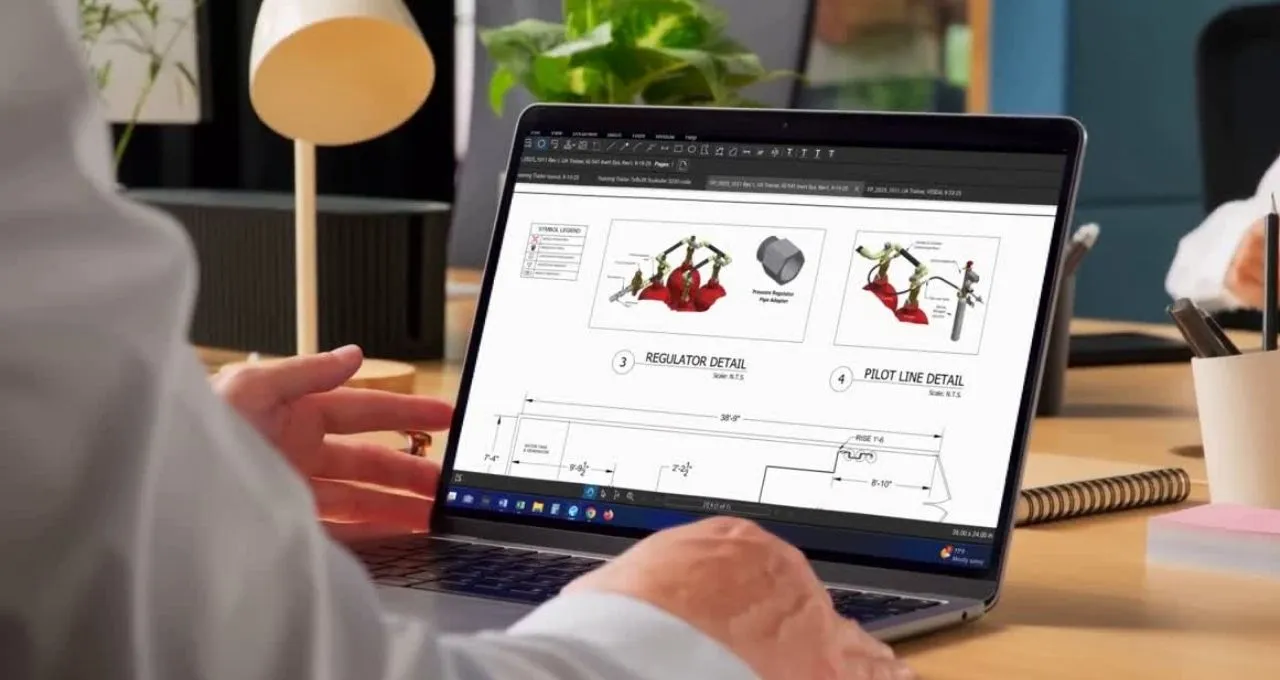

“The Fike Solution Group understood how critical uptime and cleanliness are to our customers. They want to protect their inventory from fire damage, of course. But they also want to protect their inventory and machine from water damage. Fike designed and built a system that safeguards both.”

Calvin Bowers, Senior Director of New Business at Kardex

Examples of Unique Protected Applications by FSG

Why Choose Fike Solutions Group?

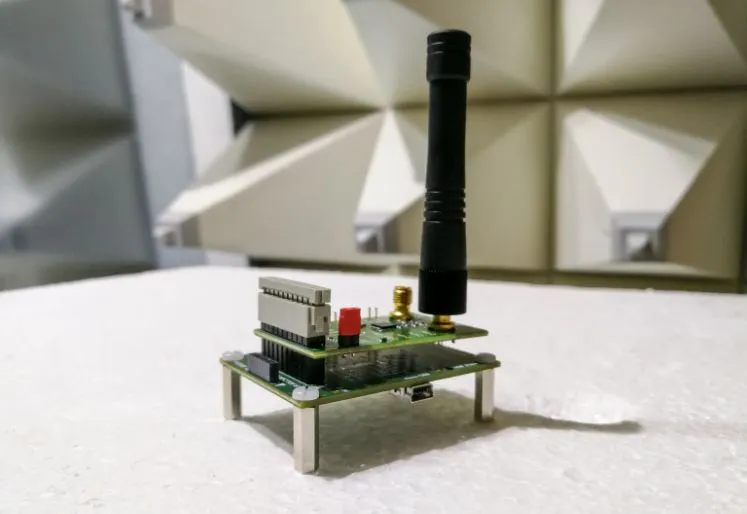

- More than 50 years of fire protection experience

- Experts in all Fike fire detection and suppression systems

- Global reach and understanding of all regional codes and standards

- Experience in nearly all industries and various challenging applications

- Network of trusted Fike partners, distributors and integrators

- Ensure that your protection strategy, deadlines and business goals are met