A lithium battery-powered device lies at the bottom of 12 inches of trash. Suddenly, it ignites, and the surrounding materials begin to heat up as well. A nearby Fire Rover system quickly detects the heat signature, and its water cannon douses the fire with a targeted deluge of water, all within seconds and well before the minor event becomes a major one.

Fire Rover is a remotely operated firefighting company that utilizes both comprehensive fire detection and suppression technologies, overseen by a team of operators, to ensure reliable fire protection for both indoor and outdoor, as well as often spacious, applications.

After years of testing, Fire Rover recently received FM approval for its remote firefighting solution, including the Fike IR3 flame detectors.

We spoke to CEO Will Schmidt and VP of Fire Protection Ryan Fogelman about their FM approval, the relationship between Fike and Fire Rover, the number of fire events that occur annually within waste and recycling facilities, and various other topics important within the industry.

Fire Rover and Fike Flame Detectors

Depending on various factors, the Fire Rover system may utilize multiple fire detection technologies, including thermal imaging cameras, smoke video analytics, and Fike IR3 Flame Detectors. Fike Flame Detectors are used in a variety of environments and applications to quickly identify the unique characteristics of flames, ensuring high reliability against false activations and detecting fires up to 300 feet away.

Will: At the core of what we try to do is detect fires as early as possible, and that's where Fike technology comes in. Since fires present in different ways, sometimes you get a thermal signature before you see flames, so thermography works well for those instances of fire. Other times, the flame and the light emitted are perfectly presented to a Fike Flame Detector.

Additionally, when we move outside of 150 feet, the flame detector is also a lot better at detecting fires than the thermography because the heat dissipates more quickly than the light does.

For example, we had an event where this small battery popped within a pile of waste and recycling materials. You can't even see it when you're looking at the video, and we had no idea what caused it.

Our operator came on and mentioned we had a false detection; however, maybe 30 seconds later she sees a little puff of smoke and watches that area for another minute or so and then sees the actual visible flame. So, it must have been a really tiny flame, and it triggered the flame detector. To get on something that early gives us a tremendous advantage of treating the fire and alerting the staff.

This is also when the flame detector is quicker to activate versus the thermal camera because something that small doesn't have much of a thermal fingerprint as it doesn’t create enough energy for a little while. Especially the further away it is from the camera, the longer it takes to detect it thermally.

So that’s one of the examples of why Fike Flame Detectors were a perfect fit, and it was due to their speed and accuracy.

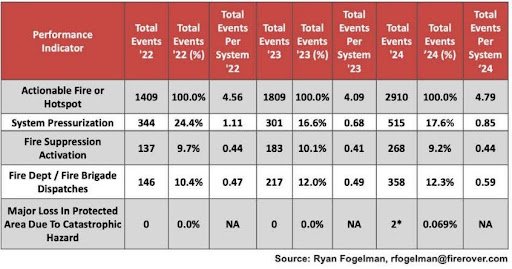

Fire Rover Performance Dashboard 2022-2024

The Importance of Accurate Detection and Human Involvement

Every time a Fire Rover system detects a potential fire, a human is always present on the other end. The operator makes a number of decisions including notification of on-sight staff, and local fire professionals as well as activating the suppression system with a targeted spray of water. Not only can our Fire Rover agents see through the smoke or darkness we are dealing with, but they also aim and accurately spray water on to hazards. Using this approach Fire Rover is able to fight these fire incidents using a mere 440 gallons on average per incident.

Will: Even with human oversight, we're still running a sophisticated network of analytics. We have an AI layer that is able to take some of the events that pass analytics, meaning they're hot or they trip one of the other thresholds, and we then put it through another layer of processing to get rid of the really simple things that we don't want to tax the operators with. But most of the more complex situations are going to go to the operator, who makes the final decision, such as determining dust or steam versus an actual threat such as smoke.

And then there are situations where you may have an incredibly hot piece of equipment that reaches certain temperature thresholds. For example, let’s say a fire occurs from a nearby circuit breaker; the AI could ignore it and believe it’s just the heat produced from the equipment.

That’s why we're always going to have a human review it because we have a zero tolerance for misses here. We just simply can't and won't accept a fire going undetected.

So, we're never going to fully automate the processing to AI because there are still false positives that we see that are close enough to a fire that we're going to have a human make the final decision.

Finally, a lot of our customers need the human involvement to ensure employees are not in the way and in danger of being struck by the suppression activity. There are plenty of instances where there's a fire and we have to stand down until people move out of the way. The last thing we want to do is have the stream push them into the fire or off of a service ladder.

That’s why our trained operators are a permanent element included in the overall Fire Rover solution.

Receiving FM Approval

In March 2025, an FM approval was awarded to Fire Rover’s Continuous Flow Solutions, validating its effectiveness against rigorous industry standards.

Ryan: We have been working with FM for over five years on the testing requirements and what it would take to fully cover our entire “smart monitor solution.” We need to follow extensive testing against multiple FM standards, including FM 1421, FM 5511, FM 3810, FM 3010, FM 3011 and FM 3260 in order to achieve this certification.

Will: We probably worked with them for about a year to just come up with how we would test our system, and overall the project was over two and a half years long. It's been a long journey but once we finally got to testing, it went fairly smoothly. We had invested a lot up front to make sure we knew what the requirements were. We did some pre-testing in some independent labs and also had an independent consulting project that we did with FM Global to help us make sure we were ready for the testing. So once it finally came down to the official testing, we were able to achieve the technical standards that were required.

Going through this process definitely raises the bar across all of our technologies. For example, before this process we weren't thinking about things like electromagnetic interference when we were designing the product the first time. However, we now know the standards that they're going to look to and that’s now included in every system moving forward.

Ryan: We started in 2015 in the back of a scrap metal facility. We didn't have millions of dollars, we didn't have the ability to go test what we did in the lab. We cut our teeth and learned, and that's why we're able to do what we do so well. Now, 10 years later, we've proven that our system works and most importantly we've proven the risk mitigation to the insurance companies so that they're able to underwrite a lot of these occupancies that are considered inherent risks.

The reality is there's no one else in the world doing what we do remotely fighting fires. We're on site ready to fight the fire within seconds to make sure we're protecting the employees, equipment and the buildings from catastrophic losses.

How Often are Fires Occurring at Waste & Recycling Facilities?

The number of daily hazards the waste and recycling industry faces—in trucks, facilities, landfills and materials recovery facilities—is increasing at an alarming rate. For a detailed report, read the 8th Annual Reported Waste & Recycling Facility Fires Report US/CAN by Ryan Fogelman.

Ryan: Fifty percent of the fires we see in waste and recycling are from lithium batteries, and the other 50 percent are traditional hazards like fireworks, chemicals and accelerants that we have been dealing with for the past 70 years. The reality is that there are billions of batteries that have been dropped into the waste stream in the past 10 years, and the battery industry has done little to help mitigate the problem.

Take vapes, for example. As these devices grow in usage by the public, they also pose an increasing threat to operators at every level of their business. Not only are their batteries being improperly discarded in waste and recycling bins, but the vape industry has done the bare minimum to invest in the technology needed to address the 1.2 billion vapes entering our waste and recycling streams annually. With little to no safe disposal options available, this problem is only expected to worsen.

2024 was a turning point, as operators and insurers finally realized that relying solely on local fire professionals as the only frontline response is no longer viable. Waste and recycling industry fires often contain hazardous materials such as batteries, accelerants and pressurized containers, making swift action necessary. However, responding quickly doesn't mean subjecting employees to these hazards without proper protection.

We here at Fire Rover are on pace to easily put out over 400 fires this year (2025). It's very odd if a day goes by that our operators aren't putting out at least one fire at one of our client’s facilities.

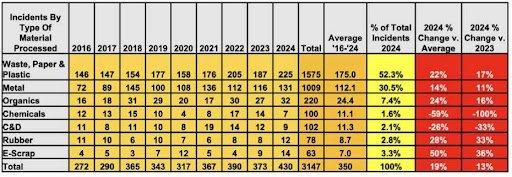

US/CAN Fires Reported in Waste & Recycling Facilities 2022-2024

About Fire Rover:

Fire Rover is a remotely operated fire detection and suppression solution that operates 24/7/365 to protect industrial and outdoor facilities worldwide, not only by detecting fires early but also by quickly fighting fires on the frontlines. Fire Rover achieves early detection of fire incidents using military-grade thermal detection equipment, smoke analytics, Fike IR3 flame detectors, and high-definition video to facilitate final verification by human agents and targeted fire suppression using onsite, PFAS-free firefighting agents. Their remote firefighters are ready to engage with local staff, local fire professionals, and onsite canons that they control remotely from the command center.

Learn more about Fire Rover at firerover.com

Learn more about waste and recycling fires by reading the 8th Annual Waste & Recycling Fire Report