Your Global Explosion Protection Partner

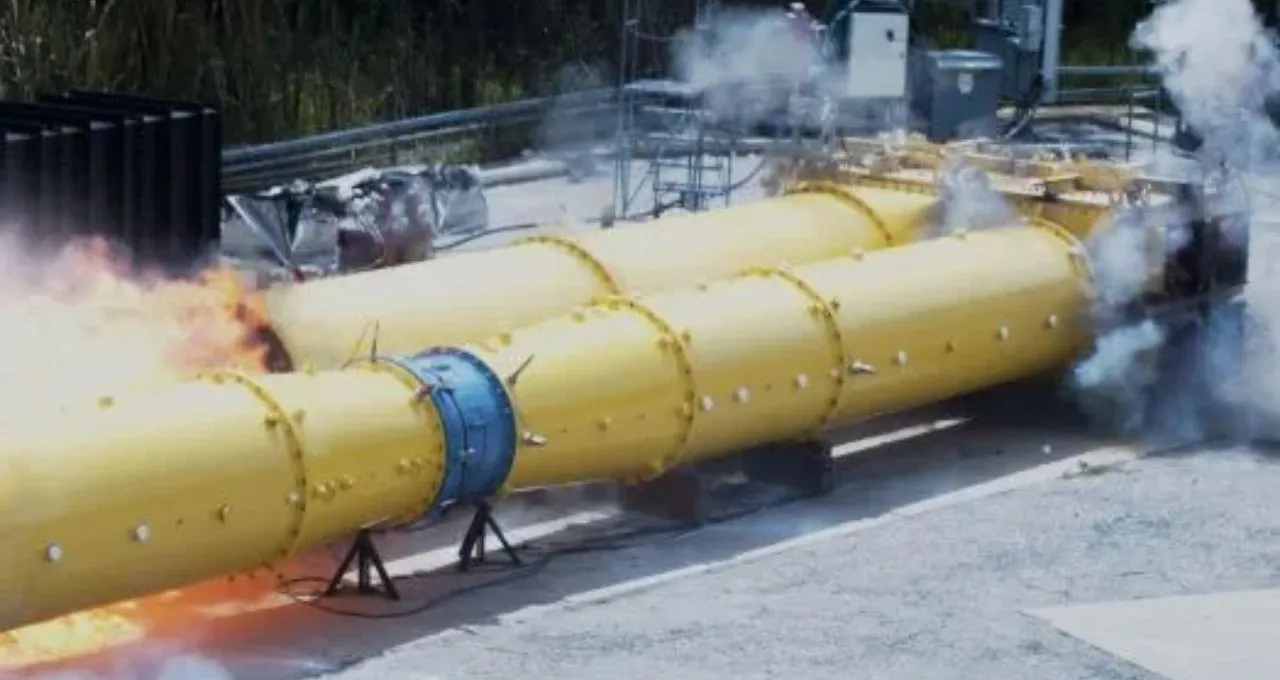

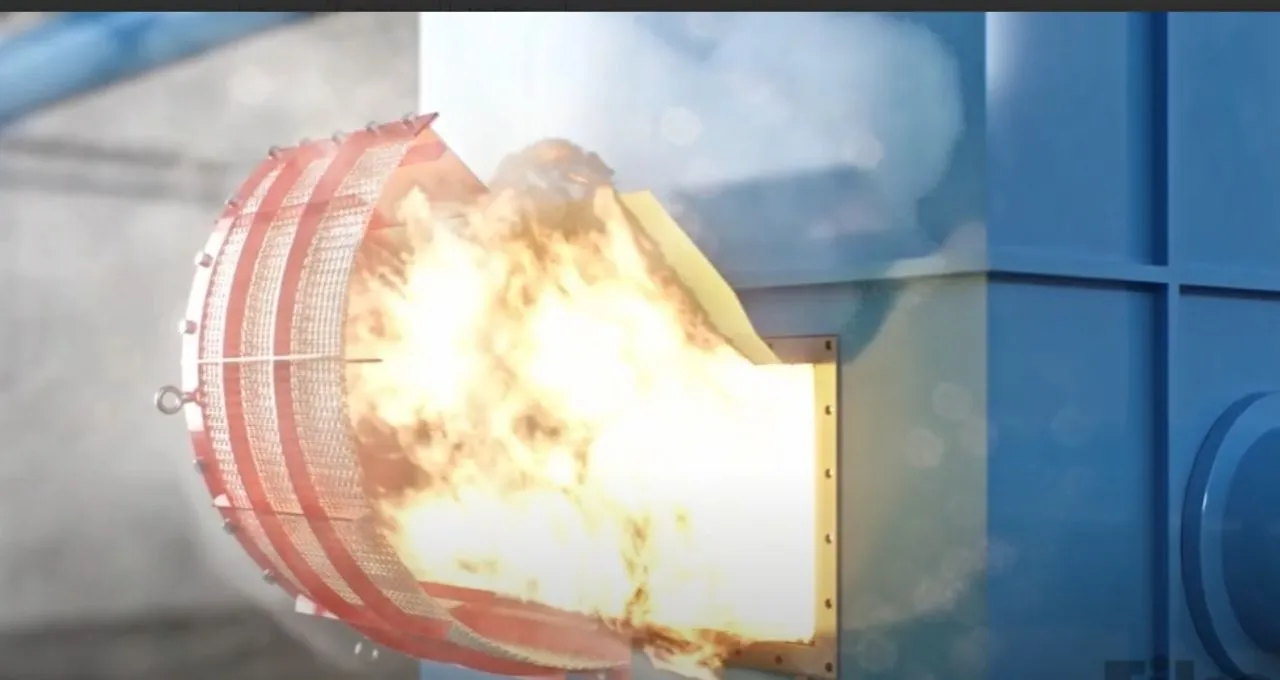

A dust explosion can result in significant downtime, insurance increases, fines, equipment and building damage, and worst of all, harm to employees. Fike’s unique ability to identify hazards, design and supply the required solutions and execute all required service protects both businesses and its workers from the dangers of combustible hazards.

What is Fike Explosion Protection?

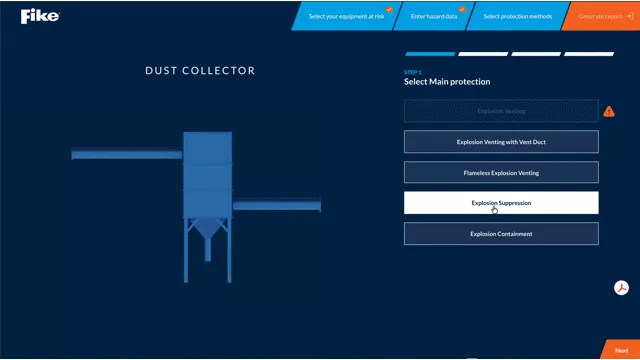

Design Your Fike Explosion Protection System

Are you wondering which Fike explosion protection solution may be recommended to protect your unique industrial process equipment?

Our easy-to-use Explosion Protection Methods Tool will indicate the possible protection strategies based on your application's:

- Hazard Type

- Volume

- Inlet & Outlet Type

- Inside or Outside Location

- And more

Global Field Service Network

We are proud to have the largest network of explosion protection technicians across the world to ensure quick and reliable service regardless of the location. You can count on us for:

Installation

Ensure all devices are installed precisely to system drawings and during a convenient time in your production schedule to minimize downtime. If your contractors are installing the system, you can expect the Fike system to be delivered on time, organized and labeled, and our team is available for assistance every step of the way.

Commissioning

Activate your process with the installed explosion protection system to ensure electrical, PLC and all other connected systems work as expected. Includes validation of operating parameters, electrical connections check, container pressure validation, panel operation training, and much more.

Maintenance

Required to comply with regional standards and ensure reliable performance of the explosion protection system if called upon. Fike's scheduled maintenance plans prioritize lead times, perform quarterly maintenance, and inspect and replace system parts if necessary, providing you full confidence that your process is safe.

Fike Labs

Selecting The Right Explosion Protection Partner

When searching for an explosion protection provider, do you know which services are important to your business? Do you know the right questions to ask?

Fike partnered with the team at Dust Safety Science to create the following checklist which details all of the capabilities an explosion protection provider should possess to help you reach combustible dust safety.

Are you ready to take the next step?

We are here to answer any of your questions with no obligation or help you begin to develop an action plan.

Already know what you're looking for?

Explore Fike's explosion protection solutions, including our deflagration vents, isolation valves, suppression systems and more.