The Problem

Fires in waste processing and recycling facilities are on the rise, resulting in increased property damage and casualties.

In 2017, 290 fires were reported in both the United States and Canada waste and recycling facilities – an average of 24 fires per month. Facility fires increased in 2018 with 363 fires reported – an average of 30 fires per month.*

This data does not include the number of unreported fires, which are estimated to be more than 1,000 additional incidents per year.

These fire hazards are most often located in the tipper floor areas, where the waste is initially discharged from trucks and moved by heavy equipment. The combination of unique fire detection challenges (high ceilings, dusty environments, heavy equipment with hot engines and exhaust) and the increasing persistence of flammable materials (lithium ion batteries, pressurized containers) in tipper floors makes traditional fire detection largely ineffective.

With the number of fire incidents on the rise, few waste and recycling facilities are equipped with today’s best solutions for these unique applications.

*Data courtesy of FireRover.com and Waste360.com

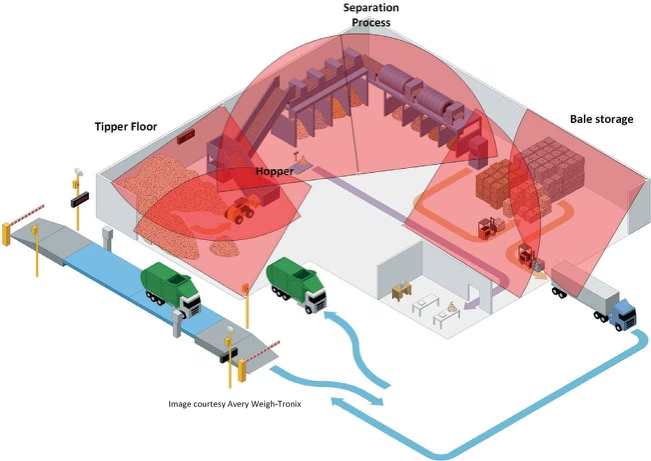

Sample Fike IR3HD Flame Detector Coverage & Detector Locations

The Solution

Fike’s extensive testing and on-site results have proven that the most reliable and cost-effective technology for early-warning detection in waste and recycling facilities is Factory Mutual-approved, NFPA 72-compliant flame detection— IR3 flame detectors with embedded HD video camera and onboard recording.

Fike’s IR3 HD flame detectors use electro-optical sensors to quickly identify unique characteristics of flames, including radiated energy, flicker signature and flame distinguishing algorithms, which can activate connected alarm or suppression systems, such as automatic water cannons or deluge systems.

The onboard camera feature also provides real-time video for central station monitoring and visual verification required for response by many fire departments.

Over the span of a five-month trial period with a major US-based waste management facility, three fires were detected and video was recorded by Fike IR3 HD detectors in the early stages of development, and before they were able to spread.

Perhaps just as importantly to the prospective client was that the trial resulted in no false alarms – a common nuisance in the industry.

The trial period was so successful that the facility is now permanently equipped with Fike IR3 HD detectors. They are now in the process of prioritizing which of their other facilities will upgrade their fire protection systems with Fike.

Unique Challenges Solved With Flame Detection

Fike recommends IR3 HD cameras over its other intelligent fire detection devices because of their success in solving the following unique challenges faced by waste and recycling facilities:

High Ceilings and Dusty Environments

Not Recommended: Traditional heat and smoke detectors are ineffective at detecting the early stages of a fire in spacious, open-air tipper floor or process buildings.

Recommended: Flame detectors can identify a fire over 100 ft. away with a horizontal 90-degree coverage area.

False Alarms

Not Recommended: Thermal radiometry in tipper floors may result in false alarms due to the high temperatures from heavy equipment’s engines and exhaust. Furthermore, thermal cameras are not NFPA 72 compliant to initiate an alarm on fire alarm panels. (Note – there may be areas where these solutions are recommended, such as targeting a hopper or bunker).

Recommended: Flame detectors have proven high immunity to false alarms against direct and reflected sunlight, incandescent frosted glass light, hot engines, vehicle exhaust and more, and they are a fraction of the cost of thermal cameras.

Obscured Flames in Waste Piles

Not Recommended: Aspirating air sampling systems detect the incipient stages of obscured fires, but the dusty, open air environment often creates logistical and maintenance challenges for these devices.

Not Recommended: Thermal radiometry’s advantage is to detect obscured smoldering; however, waste piles often have air pockets located throughout, which is more conducive to flames than it is to smoldering.

Recommended: Flame detectors contain sensors that directly receive the radiant energy emitted from flames and can detect even the smallest fires within milliseconds.

What Does NFPA Say About Flame Detectors?

NFPA 72 National Fire Alarm and Signaling Code (2019) Section A.17.8.3.2.1:

The following are types of applications for which flame detectors are suitable:

- High-ceiling, open-spaced buildings such as warehouses and aircraft hangars.

- Outdoor or semi-outdoor areas where winds or drafts can prevent smoke from reaching a heat or smoke detector.

- Areas where rapidly developing flaming fires can occur, such as aircraft hangars, petrochemical production areas, storage and transfer areas, natural gas installation, paint shops, or solvent areas.

- Areas needing high fire risk machinery or installations, often coupled with an automatic gas extinguishing system.

- Environments that are unsuitable for other types of detectors.

- The HD Camera Advantage

-

Flame detectors have the ability to quickly identify fires and relay this information to a connected fire panel within milliseconds. However, the standard version of flame detectors do not offer visibility of the protected area.

Fike “HD” flame detectors are available with this functionality by including an embedded HD CCTV camera. This technology is compatible with ONVIF S communication protocol, allowing for simple integration with IP camera networks, network video recorders and central station software integration.

Here are some reasons why this additional visibility is important to many of Fike’s waste management clients:

- Live Video Feed

-

View the alert in real time for video verification and situational awareness, determine its severity and coordinate appropriate response. Safety managers may also receive on-demand web video access, email and texts upon alarm.

- Onboard Recorded Video

-

Video is constantly recorded and may be accessed one minute pre-event and up to three minutes post-event to help determine the cause of the fire and evaluate response.

- Integrated Alarm/Video Central Station Monitoring

-

When a flame is detected, the central station receives the alarm and live video. A map of the building is also included in the alert so first responders can locate the fire quickly and safely.

Lithium Ion Batteries Fire Hazard

While data shows an increasing trend of fire incidents in waste and recycling facilities, one reason is the continued proliferation of lithium ion batteries. For example, a front-end loader may crush a lithium ion battery (either by driving over it or pushing it into the waste pile), which may create a spark and ignite nearby waste.

Lithium ion batteries may be found in more devices that you might think, including in:

- Pacemakers

- Digital Cameras

- Greeting Cards With Songs

- Smartphones

- Watches

- Thermometers

- Laser Pointers

- Calculators

- Hearing Aids

- Laptops

- And Many More